Case Studies

* and how we work

At struct.digital, we empower engineering teams to work smarter, faster, and more efficiently by delivering tailored software solutions that genuinely fit your workflows.

Our expertise spans the full spectrum of engineering automation—from automating structural calculations and optimizing material use, to seamlessly integrating all major AEC platforms (including Revit, Etabs, SAP2000, Tekla Tedds, Grasshopper, and more). We are also specialists in automating cross-discipline workflows, such as connecting geotechnical software directly with structural engineering platforms, ensuring data flows smoothly across all project stages and disciplines.

With every project, our focus is clear: maximize your return on investment and ensure complete client satisfaction.

What sets us apart?

Client-First Approach: Every client is paired with an account manager, available at all times. We believe clear communication is essential, so we provide weekly or bi-weekly progress meetings and regular updates—no surprises, no missed deadlines.

Workflow-Driven Design: Within the first two days of starting a project, we meet directly with your engineering teams to deeply understand your day-to-day processes. Our goal is to deliver solutions your teams actually use—not shelfware. We iterate with all stakeholders, gathering continuous feedback to refine and perfect every detail.

Technical Excellence: Our team combines years of hands-on UI/UX experience with deep technical know-how across all leading AEC APIs and platforms. We don’t just automate; we create software that feels intuitive, robust, and ready for the realities of engineering.

Cross-Discipline Integration: We excel at connecting geotechnical, structural, architectural, and other engineering tools, breaking down silos and enabling seamless collaboration across all project phases.

Full Transparency: From kickoff to delivery, we work in the open—sharing designs, progress, and challenges—so you always know where your project stands.

Our Promise

Your success is our measure of success. We are committed to delivering solutions that drive measurable efficiency, reduce costs, and help your engineers focus on what matters most: great design and safe, innovative structures.

Case Study #1

Project Overview

Our client approached us with several workflow challenges and a vision for three specialized applications to streamline their engineering processes. Through a series of collaborative meetings, we explored potential solutions, guiding them through user interface options, code structure, and critical considerations like human-computer interaction, code maintainability, and efficiency. While the client had a basic concept for the apps, they were open to suggestions, allowing us to refine their ideas and develop solutions that exceeded their expectations.

Solution Breakdown

1. Desk Study Automator

This application automated the traditionally manual process of creating desk studies. Desk studies involve compiling comprehensive information about a project site, including maps, reports, rainfall data, historical records, and previous construction plans. The app automates data retrieval from sources like Google Maps, Historical Maps, and Flood Risk APIs, creating structured reports. It allows users to preview and selectively include information, giving them control over the data incorporated into the final study.

2. Project Database

We designed a central database to store all essential project parameters—from loading information and construction methodologies to sustainability requirements and foundation data. This database, stored in a custom JSON format, acts as a primary information source for all project-related data and is designed to integrate seamlessly with future applications. By centralizing project data, this tool ensures consistency and accessibility for engineering teams.

3. Tedds Calculator Integration

Built on the Viktor.AI platform, this app connects multiple Tekla Tedds calculations, streamlining complex structural analysis tasks. Since Viktor.AI has limitations regarding UI and cloud capabilities, we devised innovative workarounds, such as dynamically hiding and showing UI elements based on specific conditions. Additionally, to bypass Viktor.AI’s inability to run Tedds natively, we developed a custom worker (.exe) on a remote system that receives input, processes calculations, and sends results back to the app. This custom networking solution allows for real-time feedback, ensuring engineers can conduct and document accurate calculations for major elements like concrete, steel, timber, and masonry.

Outcome

We completed these three applications within eight weeks, a challenging timeline that required rapid problem-solving, new technical strategies, and creative workarounds. The client was thrilled with the results and expressed interest in future collaborations and ongoing consultations.

This project demonstrates struct.digital’s commitment to delivering innovative, efficient, and user-centric solutions that transform engineering workflows, even within tight deadlines and complex technical environments.

Case Study #2

+

Client: Loft Bed Manufacturer

Project: Development of a Grasshopper Script for Optimized Structural Design

Background

A leading loft bed manufacturer approached struct.digital to streamline their design process and reduce material costs. They needed an automated solution that could optimize the size of steel and timber components for each loft bed based on specific customer requirements. Additionally, they required integration with SketchUp, the software their team uses to create initial bed designs, to ensure a seamless workflow.

Solution

struct.digital developed a custom Grasshopper script to automate structural analysis and size optimization directly from SketchUp models. Here’s how it works:

Input Integration with SketchUp: The script takes input directly from SketchUp, making it easy for the design team to move from concept to analysis without needing additional software. It extracts essential structural elements—such as beams, columns, and supports—from the SketchUp model, feeding these directly into the Grasshopper environment.

Automated Structural Analysis to Eurocode Standards: The extracted elements are analysed based on Eurocode standards, ensuring that each loft bed meets the necessary safety and structural requirements. This automated analysis assesses the loads and stresses on each component, providing a reliable foundation for material selection.

Material Optimization: Based on the structural analysis, the Grasshopper script identifies the smallest possible sizes of steel and timber sections that can safely support the bed structure. The script then cross-checks these optimized sizes against the manufacturer’s available stock to recommend the most efficient materials for fabrication.

Cost Reduction: By automating material selection and ensuring components are as small as safely possible, the solution reduces both material and fabrication costs. The manufacturer no longer needs to manually adjust designs to achieve optimal material usage, saving significant time and reducing the potential for errors.

Results

The Grasshopper script has transformed the manufacturer’s design workflow. What once required hours of manual adjustments and calculations is now an automated process, reducing design time by over 60% and cutting material costs by an estimated 20%. With the script’s ability to suggest the most efficient sizes from available stock, the manufacturer has also streamlined their inventory management, contributing to reduced waste and increased sustainability.

Key Benefits

Time Savings: Reduced design process time by over 60%.

Cost Efficiency: Lowered material costs by optimizing size and using stock materials.

Quality Assurance: Ensured compliance with Eurocode standards through automated analysis.

Sustainability: Reduced waste by optimizing material usage and minimizing excess stock.

Through this custom solution, struct.digital empowered the loft bed manufacturer to achieve faster, more cost-effective production with enhanced structural integrity in each design. This case demonstrates how struct.digital’s expertise in structural engineering automation can yield significant savings and improved efficiency across engineering and manufacturing industries.

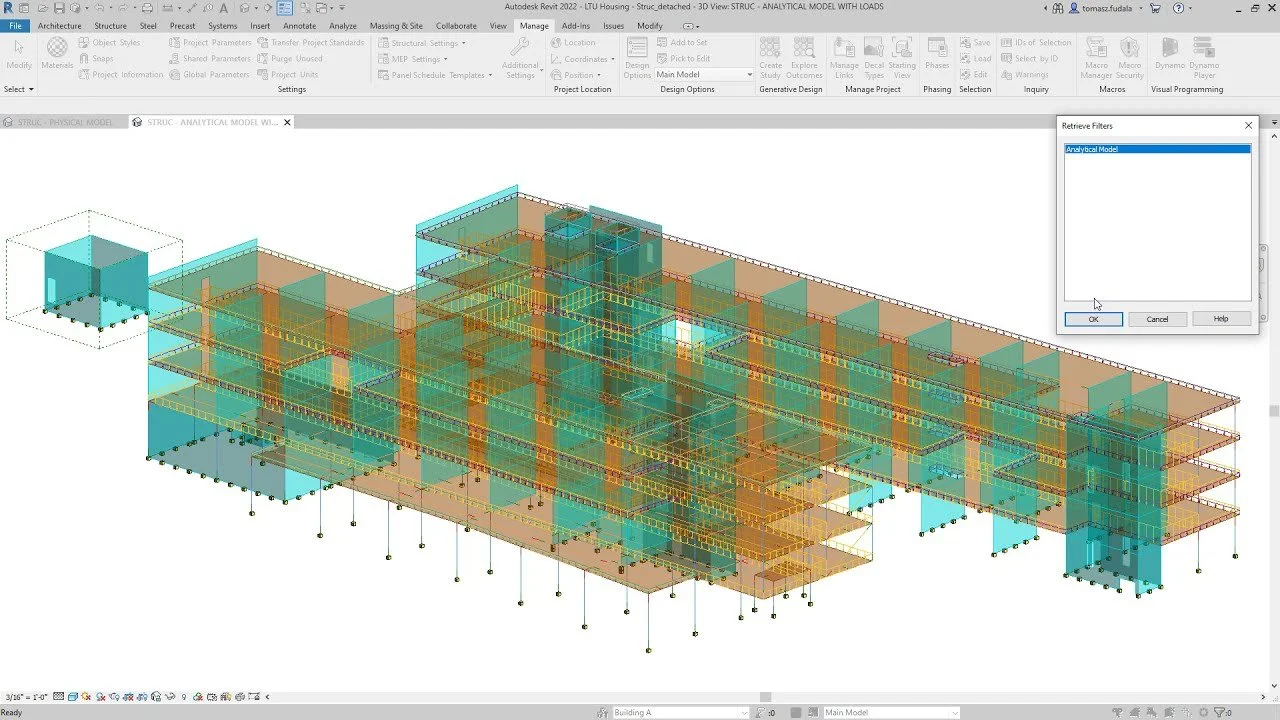

Case Study #3

Client: Major UK Engineering Consultancy

Timeline: 6 months

Project: Automated Model Translation & Structural Optimization

Background

The client needed a robust software layer to seamlessly translate architectural Revit models into actionable structural models, produce calculation packages, and automate the entire optimization process for various structural priorities such as reinforcement efficiency or material quantity.

Solution

Model Translation & Synchronization: Developed a native pipeline using Autodesk APIs to directly translate. Revit models into structural analysis-ready formats in Autodesk Robot, with naming conventions and data structures precisely matching those used by client engineers. Loading information was derived directly from Revit model.

Calculation Automation: Structural calculations were performed using both Tekla Tedds and company-standard Excel templates, fully automated and updatable as models evolved.

Optimization Algorithms: Enabled user-driven optimization (e.g., minimize reinforcement, reduce concrete volume, etc.) in line with Eurocode standards. Multiple calculation checks (e.g., buckling, axial loads, axial shortening for tall buildings) were codified, handling complex logic and validations automatically.

Live Model-Calc Linking: A custom connector kept Revit, Robot, and calculation packages in sync—any change in the Revit model instantly updated the structural model and all calculations, versioning each step for full traceability.

Validation & Error Handling: The software flagged failed or borderline elements, highlighted missing validations, and automated additional checks as required by the client’s QA processes.

Challenges Overcome

Integrating diverse tools (Revit, Robot, Tedds, Excel) with minimal user intervention

Codifying complex engineering rules and exceptions (e.g., multi-check scenarios for certain structural elements)

Ensuring robust version control and error validation in dynamic environments

Achieving user acceptance by matching all nomenclature, workflows, and calculation outputs exactly to client standards

Key Benefits

80% reduction in repetitive modeling and calculation tasks

Near-zero manual intervention after implementation

Improved error detection and design safety